The 3D printing market is set to enter into a stage of maturity as it already has insinuated many industries. From integrated supply chains in manufacturing to customized prosthetics in healthcare, 3D printing has revolutionized various industries.

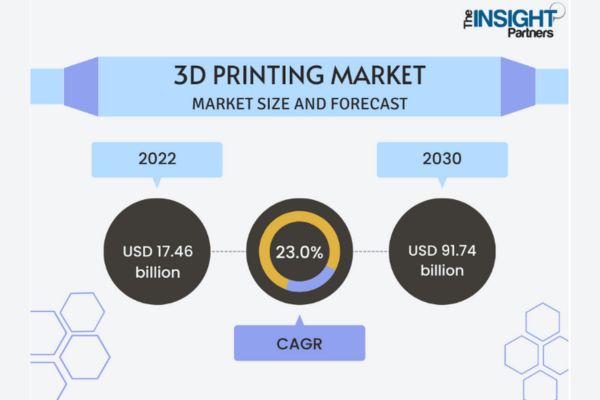

The Insight Partners, predict that the 3D printing market is likely to cross a valuation of USD 91.74 billion by the end of 2030, from the valuation of USD 17.46 billion in 2022. The market is estimated to garner a CAGR of 23.0% in the forecast period i.e., 2022-2030.

This article intends to take readers through some latest 3D printing developments and trends shaping the sector globally. Moving further it will offer insights on approaches needed by entrepreneurs to overcome challenges ahead in the massive 3D printing aisle.

In response to the evolving competitive landscape, many companies are adopting innovation. A new class of quality machines is foreseen to positively influence speed and agility. Today 3D printers have a greater ability to deliver 3D-printed parts with excellent designs. Cost-effectivity is a strategic benefit of 3D printing that has led to changes in how goods are being manufactured. The mass customization trend is expected to continue in the future. This article will cover recent developments in skyrocketing niches of 3D printing.

Integrated Supply Chains – Umbrella of Industry 4.0

In 2023, the US Department of Défense (DoD) announced the policy “Additive Manufacturing for Military and Défense” according to which DoD was to spend about USD 300 million on AM. These initiatives have led foundations for the coming decade. Supply chain resilience is crucial under the umbrella of Industry 4.0. Investing into AM may not be a panacea for all issues of logistics and ecology, but it’s closer to tackling them.

Covid-19 has exposed lacunas in conventional manufacturing methods. Greater emphasis is given on fostering supply chain resilience post pandemic is foreseen to drive massive transformation. The 3D printing market in particular is rising in popularity and can withstand changing supply chain strategies globally.

Passage of the CHIPS Act by the U.S. is another measure demonstrating the country’s commitment to building robust supply chain networks. It also highlights the openness of companies to leverage 3D printing technologies to achieve new targets. Regulatory measures supporting 3D printing market players to collaborate and change the way goods are produced.

Tech Trends in Construction 3D Printing Market

Additive manufacturing is being used in many sectors, most prominently in the construction sector. Technological marvels of 3D printing and artificial intelligence are soon expected to reveal the first 3D-printed house in Portugal. The cost-effective housing is anticipated to bring upward traction in the construction 3D printing market by 2030.

3D-printed house consumes 67% less energy than conventional houses. It’s further expected to reduce 42% of global carbon emissions by the construction sector. The use of AI in interior and exterior is a technological breakthrough for the construction sector.

The Food 3D Printing Market – Flexitarian Nutrition Trends

The technology of 3D printing has an indisputable benefit if used to offer customization in terms of size, shape, flavors, and nutritional stability of food. The 3D printing process focuses on the integration of different food ingredients into a single process. Oreo leveraged the possibility and served tailor-made sandwich biscuits with a 3D-printed cream filling of customers’ choice as per their demand.

The food 3D printing market is driven by factors such as accelerated adoption of 3D printing, and emphasis on reducing food wastage. 3D-printed food can be manipulated to target individual customers’ nutritional needs. The adoption of 3D printing as a food technology is anticipated to ensure uniformity in case of mass food production.

Companies can customize culinary creations using 3D printing technology. The 3D printed meat segment is projected to garner significant market share in coming years driven by vegan and flexitarian eating practices. Increasing preference for 3D-printed food is also driven by rising issues of livestock and propelling demand for meat alternatives.

Development of 3D printed hands – The Future of Prosthetics 3D Printing Market

Prosthetics is anticipated to continue as a key application segment in the evolving 3D printing technology. The processes and techniques are refined while creating and offering tailored prosthetics as per the needs of individuals. These prosthetics can be modeled in CAD (Computer-aided designs) software. With this software, any defects in 3D printed parts can be modified and reprinted for better outcomes and to address patient comfort.

3D printers allow the creation of more customized 3D implants. With the complex geometrics parts that can be fragmented quickly, the patient’s satisfaction rate could be improved. Items like tooth implants and knee replacements are some key segments where the use of 3D printing technology has proven to be most efficient. With the ongoing pace in technology, we expect the extension of 3D printing to the creation of 3D-printed organs. This possibility is foreseen to dramatically improve outcomes for patients in the queue for dental implants.

3 Decades of 3D printing – Transformation in Additive Manufacturing (AM)

Additive manufacturing (AM) has become a sensible way to fabricate some products such as dental aligners, interior aircraft ductwork, and manufacturing aids of all kinds. In the next phase additive manufacturing is foreseen to grow and reach mainstream manufacturers who seek competitive advantage. Healthcare companies opting for global supply chains to make healthcare more patient-centric in the future. Automotive sector players are focusing on customized cars, while customized eyeglasses are soon to become common in the consumer electronics domain. Overall emphasis is shifted to cutting emissions and using more renewables.

- NASA’s two years of research and development resulted in the creation of lightweight 3D-printed parts intended to be used in space travel and international space stations.

- Recent clearance of single-piece 3D printed dentures by FDA in 2021, is a breakthrough for the U.S. as more than 4.2 million dentures were crafted.

- Surgeons have been successful in 3D printing models of patients’ anatomy for complicated processes. 3D printing is turning complex issues into operable conditions.

- In the Tokyo Olympics in 2020, the Korean archery team could continue their dominance aided by 3D printed grips developed by the automotive brand Hyundai.

Despite commendable achievements using 3D printing technology, there is a long way to go for 3D printers and AM. This is how 3D printing finds its place in today’s manufacturing industries overcoming challenges.

| Challenge | Approach |

| Transformation from B2C, B2B, and BeyondFrom print shops to motorbike repairs the market is changing rapidly. Understanding the needs of everchanging client propositions and business needs, market players need to realign their vision of what is next for business | Focus on Up-skilling and Actionable Plan Companies willing to excel in the growing 3D printing market anticipated to compete for in-house expertise as a challenge. These companies are more likely to focus on training employees on additive manufacturing and hiring personnel with previous expertise in 3D printing knowledge. When examining the potential of manufacturing partners, companies need to consider wide criteria into account considering ability to scale, experience, and pricing. |

| Availability of Suitable Material for 3D Printing The 3D printing market players face challenges in terms of high-quality 3D printable materials. It is difficult to maintain durability requirements such as strength which may not always fit conventional materials. The development of suitable 3D printing material has just begun and it has a long way to go. | Product Research and Innovation In some sectors, the 3D printing market is still on a steep incline. Initially, the market focused majorly on prototyping rather than the development of suitable materials. However, due to the latest technologies, the development of materials has grown tremendously. Carbon-reinforced polymers are anticipated to remain the dominant segment due to strength comparable to metal. |

Regional Growth Dynamics

As per The Insight Partners’ “3D printing market report”, the Asia Pacific region is expected to witness significant growth in the prospering market in the forecast period 2022-2030. China held a major share of the market during 2022. The market is projected to witness tremendous growth due to fostering demand for automobiles in the region. Japan is one of the leading countries globally due to cutting-edge technology. Automotive manufacturing contributes to almost 89% of the manufacturing sector. Various Japanese companies are expanding their production capacities to capture existing market gaps in the automobile sector.

Future Outlook

Over time the use of 3D printing has evolved beyond fast and inexpensive prototyping to accommodate more companies to explore full-scale production. An increase in use cases and additive manufacturing materials will favor the 3D printing market growth. Inorganic and organic growth tactics are foreseen to foster new product launches, partnerships, and investment in 3D printing technology. Research and development of complex multi-material 3D printing systems are foreseen to unfold new combinations and integrate new functions into tools. Additive Manufacturing Technologies (AMT) and Selective laser sintering (SLS) seem promising high-throughput 3D printing technologies for the future.